Press release -

Morrow Batteries announces significant development milestone with the production of A-sample LFP cells

Morrow Batteries ASA (Morrow) has successfully developed its first LFP battery cell.

“We are happy to announce that we have produced, certified and delivered A-sample LFP battery cells to select customers. I congratulate the dedicated team on this achievement after lots of hard work”, says Dr. Rahul Fotedar, Morrow’s Chief Technology Officer.

The A-sample is the first step toward commercial production of Lithium Iron Phosphate (LFP) batteries. The company is on track to start B-sample production in March, followed by finishing the C-sample and mass industrial production in Arendal, Norway, in 2024.

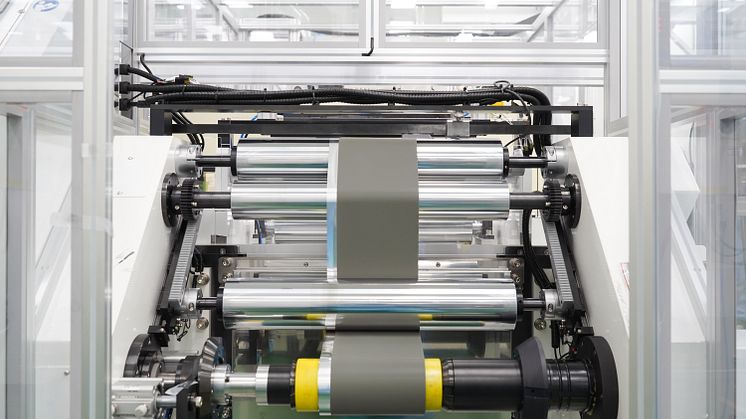

The company has now set up a Customer Qualification Line (CQL) which is temporarily commissioned in South Korea. The line will be fully operative in a few weeks, producing several thousand final format prismatic cells monthly. The pilot production site has similar properties to the Gigafactory being built in Arendal.

“We are now writing the first chapter of the Morrow story. Clocking in these milestones in the first quarter, we’re delivering on our ambitious plan, and on track to start industrial-scale production of LFP batteries in Arendal next year,” Fotedar adds.

The LFP battery cell is the forerunner to Morrow’s innovative next-generation LNMO batteries, which are being developed in parallel. LNMO is a cell that can compete with NMC in terms of high energy density but has 60% less nickel (Ni) than NMC.

Both the pilot line in South Korea and the Gigafactory in Arendal are suited for production of both LFP and LNMO batteries.

Morrow and its partners are now using the LFP A-samples to test facilities and processes. The battery is suited for standard-range vehicles, trucks, machines such as forklifts, and energy storage systems (ESS). Morrow has started discussions with customers about the LFP batteries.

“LFP batteries are produced without the need for cobalt and nickel, which reduces sourcing difficulties and ensures a product that is more cost effective and sustainable. Morrow’s batteries will be produced in Arendal, Norway, powered by Norwegian hydropower, and we aim to use only European minerals thus avoiding the ethical and cost concerns usually associated with minerals sourcing in our future, commercial production,” says Fotedar.

The A- sample cell has passed several safety and transport tests such as UN38.3, UL9540A, IEC62619 and IEC62660-2.

Topics

Morrow Batteries ASA (Morrow) is an industrial battery technology company on a mission to develop and deliver next-generation batteries with cathode material (LNMO). These batteries replaces cobalt, reduces nickel and lithium, and maximizes the use of clean and abundant manganese. Founded in 2020 and headquartered in Arendal, Norway, the company counts 130+ battery specialists across four offices internationally. Learn more at morrowbatteries.com and @MorrowBatteries on LinkedIn.