Press release -

Morrow Batteries sends certified LFP B-sample batteries to customers, taking yet another step towards GWh scale production

INDUSTRIAL UPDATE:

Morrow Batteries ASA («Morrow»), the industrial battery technology company, has produced and certified LFP B-sample batteries that are now ready for shipment to potential customers for further validation.

“We are pleased to reach this significant operational and technological milestone. Completing multiple international acceptance tests with strong results brings us to the production phase. This is a breakthrough for Morrow as we prepare for GWh scale battery manufacturing in Norway”, says CEO Lars Christian Bacher.

Excellent quality features

The LFP B-samples are produced at Morrow’s Asian facilities. The cells have been through a thorough internal acceptance test phase over the past months, showcasing excellent quality and safety features and matching all internal acceptance criteria.

“Besides the industry standard tests, our LFP B-cells passed the rigorous IEC 62660-3 compliance test conducted by Technical Inspection Associations (TÜV). The cells have been through mechanical shock, crush tests, high-temperature endurance and cycling, external short circuit, overcharge, forced discharge, and internal short-circuit”, says Dr. Rahul Fotedar, Co-Founder and CTO of Morrow.

“Battery technology development and manufacturing comes with multilayered complexities. By delivering certified B-samples, we have further reduced our operational risk”, Dr. Fotedar continues.

Morrow will ship 300-500 certified LFP B-samples to potential customers over the coming months.

According to plan

The final LFP cell validation is according to Morrow’s operational plan.

“Completing the B-samples and approaching full-scale production in mid-2024 proves the quality of our industrial platform and commitment to becoming a leading battery producer in Europe”, says Bacher.

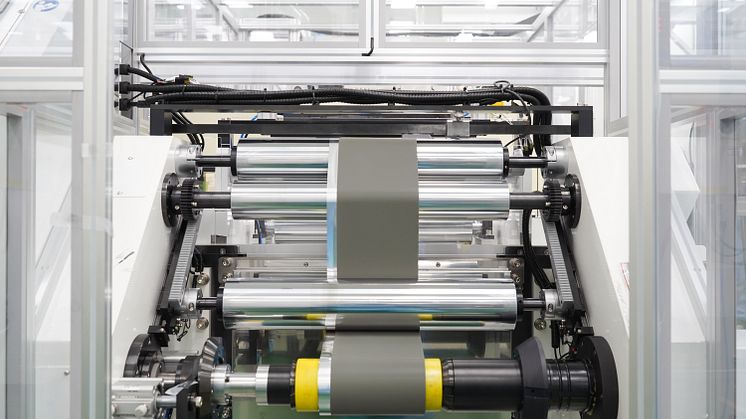

Morrow is now installing production equipment in the Morrow Cell Factory, with 51 containers arriving last week and another 450 expected over the following weeks.

Production of the LFP samples is an essential milestone in Morrow’s accelerated development of its first-generation batteries (LFP and NMC). In parallel, the company is developing its proprietary second-generation battery technology (LNMO-C and LNMO-X), with the first prismatic battery cell expected in early 2024. Morrow has established Norway’s largest centre for battery research in Grimstad, with 80 researchers, engineers, and technicians to develop their battery technologies and deliver customised battery solutions on a large scale.

***

About Lithium Iron Phosphate (LFP) batteries

- Lithium Iron Phosphate (LFP) is the industry-leading battery technology for energy storage. It is also widely used in the automotive industries and the first-generation battery technology produced by Morrow.

- LFP battery products are cost-effective and offer excellent safety features, making them ideal for stationary energy storage applications. LFP batteries have a longer cycle life and higher thermal stability.

- In addition to the standardised UL9540 A and UN38.3, the LFP B-samples made by Morrow have passed IEC 62660-2, IEC 62619 and recently, the more stringent IEC 62660-3 compliance test.

- The Technical Inspection Associations (TÜV) in Germany has conducted the tests, including mechanical shock, crush tests, high-temperature endurance and cycling, external short circuit, overcharge, forced discharge and internal short-circuit.

- Learn more about IEC standards.

- Read about Morrow products and technologies here.

About the battery cell validation process

- In battery cell production and research, “A-Sample” (Alpha Sample) and “B-Sample” (Beta Sample) refer to different product development stages.

- Morrow sent LFP A-Samples to customers for testing and customer qualification in February.

- The B-Sample is a more refined prototype built after incorporating feedback and changes from the A-sample evaluation.

- The LFP B-samples are used for final validation before mass production. Any changes after this stage might be minor and related to optimising the manufacturing process or improving product reliability.

Related links

Topics

Categories

Morrow Batteries ASA (Morrow) is an industrial battery technology company on a mission to develop and deliver next-generation batteries with cathode material (LNMO). These batteries replace cobalt, reduce nickel and lithium, and maximise the use of clean and abundant manganese. Founded in 2020 and headquartered in Arendal, Norway, the company now has 150 battery specialists across four international offices. Learn more at morrowbatteries.com and @MorrowBatteries on LinkedIn.